Design Of Fasteners Industrial

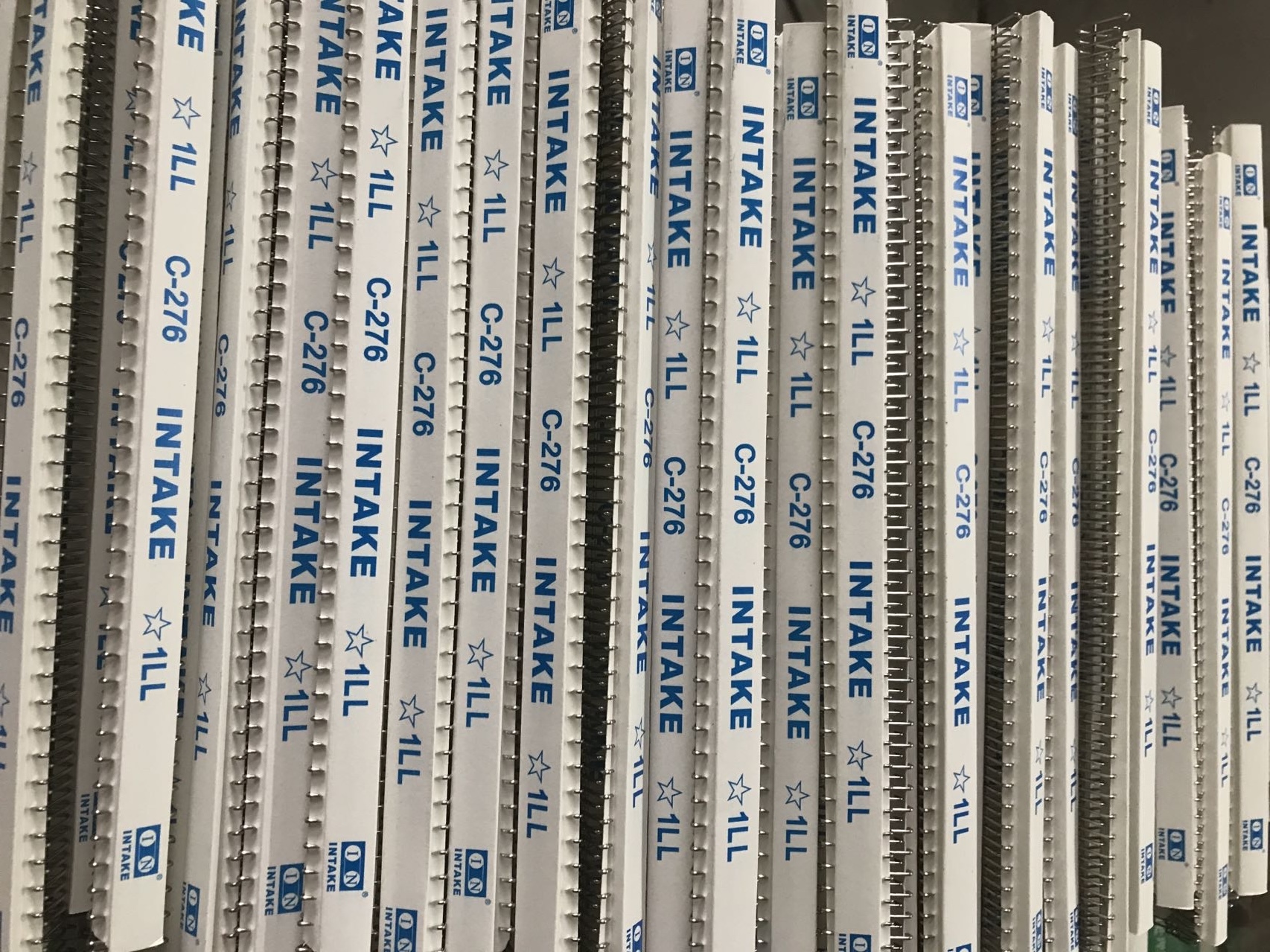

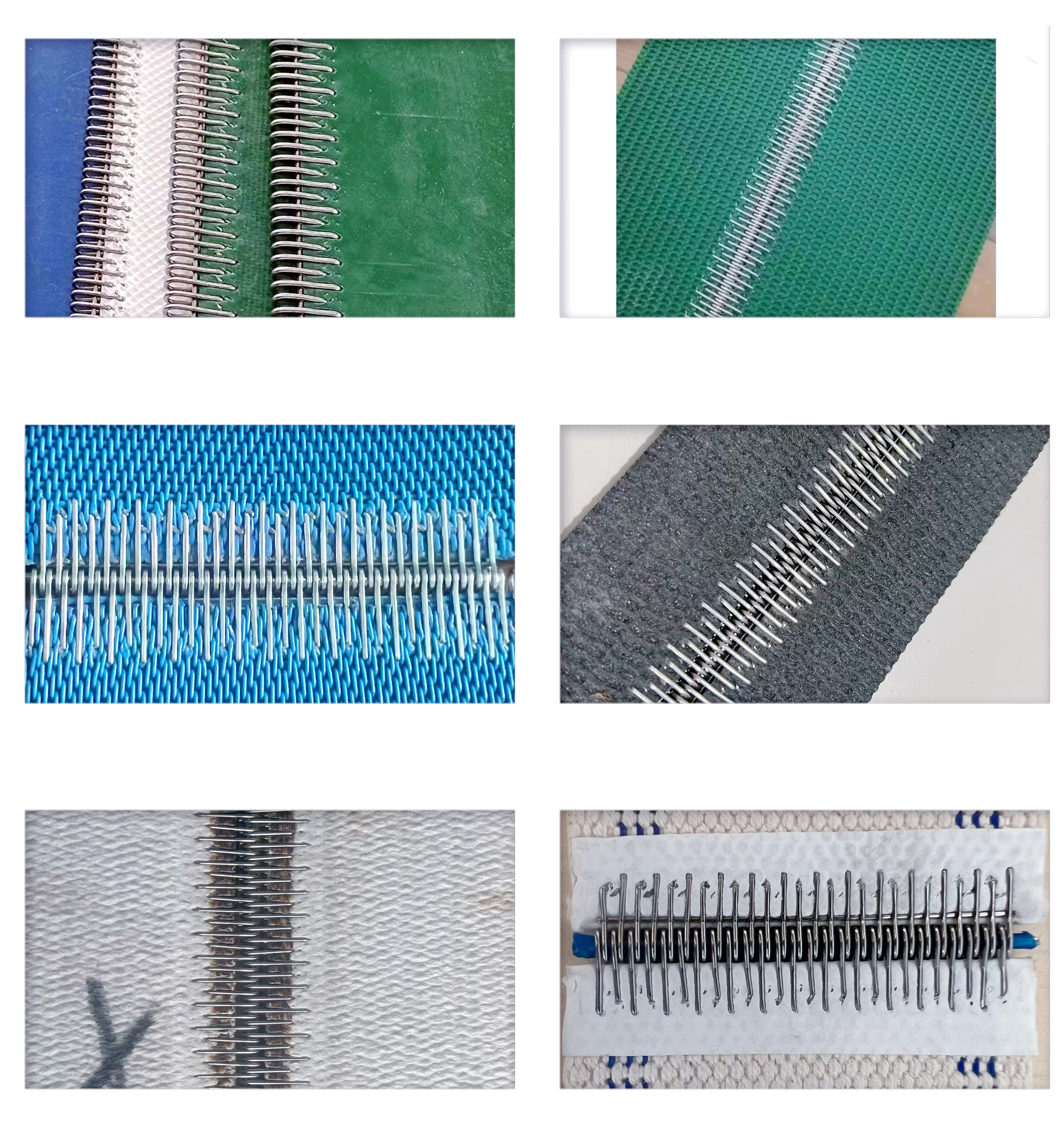

- Design Variety: Fasteners come in an extensive range of designs, including bolts, screws, nuts, washers, and specialized fasteners, catering to diverse applications and industries.

- Material Selection: Innovations in materials such as high-strength alloys, plastics, and composites enhance performance, reduce weight, and improve corrosion resistance.

- Precision Engineering: Advanced manufacturing techniques like CNC machining and 3D printing allow for precise tolerances and complex geometries, ensuring optimal fit and function.

- Customization: Rapid prototyping enables tailored solutions that meet specific client needs, facilitating quicker iterations and efficient design modifications.

- Performance Optimization: Finite Element Analysis (FEA) and simulation tools are increasingly utilized to analyze stress, fatigue, and load distribution, maximizing reliability and longevity.

- Market Trends: The shift towards lightweight and sustainable materials is shaping the fasteners industry, aligning with global trends in energy efficiency and eco-friendliness.

- Standardization vs. Innovation: While industry standards provide foundational frameworks, there’s a constant drive for innovative and adaptive fastener solutions to meet evolving technological demands.